Xiaoping: A Breakthrough In The Industrialization Of High Performance Fibers

On June 16th, at the China chemical fiber science and Technology Conference (Lianyungang 2016) held in Lianyungang, President Duan Xiaoping of the China Chemical Fiber Industry Association published the title "

Scientific and technological progress and development of China's chemical fiber industry

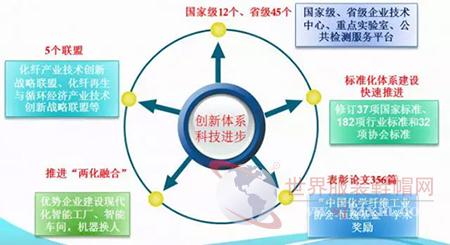

The speech reviewed the development of science and technology in the chemical fiber industry during the "12th Five-Year" period, and pointed out the key tasks of the scientific and technological development of the chemical fiber industry in the "13th Five-Year" period, and put forward development proposals, policy recommendations and safeguard measures for major projects.

"12th Five-Year": the level of technology in the industry has improved significantly.

The overall technological progress is remarkable.

Significant breakthrough has been made in the industrialization of high performance fibers.

In 2015, the total capacity of domestic high-performance fibers reached 150 thousand tons, achieving an export volume of 38 thousand tons.

High performance fiber industry

The overall technology has reached the international advanced level.

New progress in core technology of bio based chemical fibers and raw materials

In 2015, the total production capacity of the new bio based fiber reached 400 thousand tons.

We should make full use of resources such as agricultural products, crop waste, bamboo, linen and fast-growing forests to achieve renewable, biodegradable and recyclable resources.

Green manufacturing technology promotion and recycling system construction has achieved remarkable results.

Significant progress has been made in building the support system for scientific and technological innovation.

{page_break}

13th Five-Year: eight goals and ten tasks

Eight main goals

1. speed up differentiation.

Functional fiber

The development and professional application emphasize multiple technology integration, enhance the added value of products, establish efficient platform for the development and promotion of new products, and the difference rate of chemical fiber reaches 65%.

2. breakthroughs in the key technology bottlenecks of a number of high-performance fiber industrialization, comprehensively improving the quality and stability of high performance fibers and application performance, achieving low cost and high added value of high performance fibers and products, enhancing product competitiveness, and high effective fiber production capacity reaching 260 thousand tons.

3. to break through a number of key technologies and equipment for the industrialization of bio based fibers, and promote the development of bio based fibers and their raw materials, and the production capacity of bio based fibers reaches 900 thousand tons.

4., supporting a batch of recycled high quality technology of waste polyester fiber, and recycling and reuse of waste textiles, the key technology of industrialization of chemical methods. The total amount of fiber will continue to grow, and the recycling system will be further improved. The proportion of recycled fiber to chemical fiber will reach 12%, with an average annual growth of 15%.

5., support a group of key technologies for making industrial textiles with fibers, expand the application of chemical fiber in the industrial field, and increase the proportion of industrial fiber to 33%.

6., supporting a number of key technologies of green, low carbon, energy saving and emission reduction in a number of chemical fiber industries. The unit value added energy consumption, water consumption and main pollutants discharge reach the state binding targets and related standards.

7., with the core technology of a number of independent intellectual property rights, the authorized invention patent increased by 15% annually. The proportion of R & D expenditure of large and medium-sized enterprises accounted for more than 1.2% of the main business revenue, and the proportion of new product output increased to more than 28%. The construction of industrial innovation platform further promoted and played a key supporting role.

8., we have a number of chemical fiber safety evaluation and basic general standards, further optimize the standard system structure of chemical fiber, formulate standards for chemical fiber groups, enhance international standardization capabilities, and lead the development of international standards to 6.

Ten key tasks

Major key common technologies include tackling key technologies and equipment engineering technologies for high-performance fibers with low cost and high stability.

Tackling key technologies of efficient, flexible and integrated manufacturing of general fiber, key technologies for low cost preparation of new polyester industrial filament, new type of functional and intelligent, high efficient controllable scale preparation and application technology of nanofibers.

To overcome the substitution of petroleum resources for bio based materials and bio based fiber green processing technology, equipment integration technology; PLA, PDT, PTT and other biologically based synthetic polyester high efficient continuous polymerization technology; bio technology polyol engineering and industrialization of key technologies; biomedical fiber and products, biodegradable fiber and products, biological fiber based resources, efficient cleaning and high value-added products key technologies.

Tackling key technologies for recycling high quality recycled fibers.

Tackling key technologies such as digitalization, intellectualization of complete sets of equipment and manufacturing of chemical fibre, automation and traceability of products with large capacity and multiple batch numbers.

Green manufacturing technology includes 8 energy saving and emission reduction technologies and 3 green fiber manufacturing technologies.

Major technology needs to break through 3+1.

To improve the application level of information technology, it is necessary to apply information technology and advanced measurement and control technology to the whole process management of chemical fiber manufacturing.

Develop production oriented manufacturing execution system (MES), ERP information system for enterprise management, supply chain and downstream e-commerce service platform and marketing management system of Internet of things.

Strengthen the development and application of online detection, remote diagnosis and operation and maintenance functions.

Research on the application of big data technology in production, encourage and support the development and popularization of digital process design, digital whole process manufacturing technology and digital production management technology.

Using modern information technology to improve the service level of enterprises.

To guide the chemical fiber enterprises to insert services into all links of manufacturing and marketing, and encourage enterprises to extend business to R & D, design, logistics, finance leasing, information technology services, energy saving and environmental protection services, testing and certification, e-commerce, after sales service, human resources, brand building and other service areas to provide customers with systems and value-added services.

We should use the "Internet +" mode of thinking to innovate the business mode, integrate resources, and build a comprehensive supply chain management service mode, and build a high level service flagship enterprise.

- Related reading

Alibaba Founder Ma Yun: What Is The Only Criterion For Evaluating The Electricity Supplier Industry?

|

Li Guangdou'S Interpretation Of The Correct Way To Open Up Brand Internationalization Strategy

|

What Is The Reason Why Li Ling Does Not Support Department Stores To Make Full Channels?

|- Fashion makeup | Young People's Fashion Colors And Designs Are The Finishing Touch.

- Shoe Express | The New Brand Of The New Boots Is Coming Soon.

- DIY life | Mysterious Single Product Joint Jersey Series Is About To Debut.

- Fashion shoes | Sports Shoes, Cartoon Sense And Color Appreciation

- Fashion makeup | Stream Bag Brand Series Appreciation

- Fashion posters | The Completion Of Fashion Depends On The Five Fifties Of The Face.

- Fashion posters | The Little Fairies Of The Big Chest Wear Thin Clothes, MM Undressed With Meat.

- Fashion character | Second, Kill The Passers-By And Meet A Jiao.

- Fashion character | The "Butterfly Buttocks" Of The Beautiful Creature, "Di Li Ba", Is Just A Look.

- Fashion character | When Gloria Tang Crashed Into Hsu Chi, He Discovered That Exposure And Sex Are Two Different Things.

- Internet Women'S Clothing Brand ZIMMUR Crazy Shop, Why?

- Vans2015 Sales Exceeded 14 Billion. How Did It Do That?

- These 7 "Mindset" Textile Enterprises Will Be Eliminated.

- Recently, The State Administration Of Taxation Exposed 10 Cases Of Cheating Export Tax Rebates.

- No Longer Tolerate High Rent. 420 Merchants Bid Farewell To Hanzheng Street.

- What Is The Strategic Reflection Of "Strategic Single Product"?

- 2016 China Haining Tide International Exhibition Fashion Industry Summit Summit Opens In Haining

- Arthur Launched A Breakthrough Lightweight Shock-Absorbing Running Shoes.

- "CNC Generation" To Accelerate The Pformation And Upgrading Of Quanzhou'S Manufacturing Industry

- Outdoor Sporting Goods Retailers Are Developing Upstream.