Look At How Three Shoe Enterprises Go From Small Workshops To Information Chemical Plants.

North shoe city 40 years: from small workshop to information chemical plant

Three stations

Shoe making industry

It began in 1976 and has been known as the "northern shoe capital".

Up to now, the town has more than 700 shoe making enterprises, 85 thousand employees, and nearly 200 million pairs of shoes each year, with a sales income of about 4000000000 yuan.

"We are the second generation of shoe business here."

The biggest shoe maker in Tianjin

shoe machinery

Wang Hui, his boss, introduced to us.

It is reported that in the early years

Three shoe companies

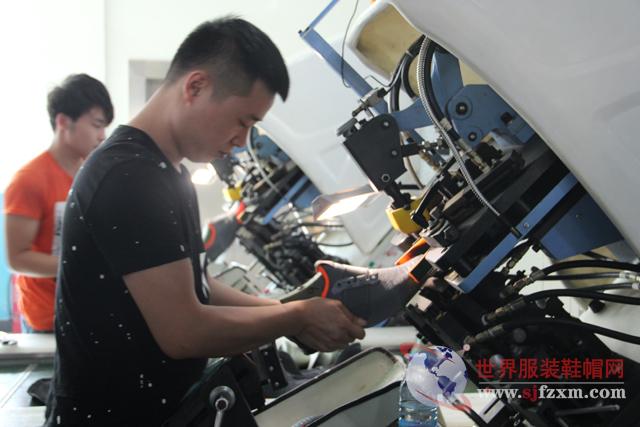

Generally it was farmers who started their jobs in small workshops, but in 2003, after reaching the line operation, the mechanization of the three footwear industries began to increase gradually.

The popularity of pipeline has led to the pformation of product structure.

In the early years, there were cotton shoes, snow boots, leather shoes and four seasons shoes.

But with the change of climate in the north, the three main shoe making products gradually turned into tourist shoes and sports shoes, and were finalized after 2008.

"Up to now, the three shoe industry chain is gradually intact, and the whole plant equipment will be our advantage later."

Wang Hui said: "I dare say that the sense of" machine substitution "is the strongest among the three shoe manufacturers. According to the observation, the labor force here is more young than other shoe producing areas, and the acceptance of advanced machines is even higher, which will become the potential potential of the three footwear industry in the future.

This situation became more evident after the first China (three) footwear industry exposition 2016.

From the exhibition, he bought a laser cutting machine shoe enterprise harmony Xi Zi Wang, and asked the supplier to connect the equipment data with the whole plant.

"In the future, the big data we produce and sell must be opened up so that shoe factories can realize information."

His boss, Xiao Fusan, said.

Occupy the first line of business: upstream and downstream collaboration and quick response

But what really makes the three shoe industry sustainable development is its superior geographical location.

The three towns in Anxin county are located in the Beijing, Tianjin and stone triangle areas, which have successfully covered the northern market.

Transportation logistics costs are low, and can quickly get feedback from the market.

With this advantage, the three shoe industry's biggest feature is the formation of a fast response production and sales mode.

"The bosses here are very hard-working and communicate with each other."

Kang Jiaqi shoe boss Wang Xiaofen said.

The three shoe companies have an amazing sense of smell for the market. Usually a shoe sole can be processed in 3 to 4 days.

"Today's shoes will be on sale tomorrow."

Zhao Baoling, from the trillion shoe industry, said.

"Products must continue to follow the needs of the market, and sometimes development is not the most important, because it does not necessarily match the market."

Liang Zhenjiang, the boss of the ten wolf shoe industry, who owns the famous trademark of Hebei, sighs with emotion. "Our edition teacher should not only connect with production, but also face the market."

At the same time, the collaboration between upstream and downstream is also the basis for quick response.

Xinhua shoe material is the largest shoe material enterprise in the region, and its boss, Wang Wei, is also the Secretary General of the shoe industry association of Anxin county.

He said: "equipment manufacturers, shoe manufacturers and shoe factories are working together, and now we have a tacit cooperation."

For example, Jinxin shoe machine, they inspect the equipment on the one hand, introduce genuine and advanced machines, and walk into the shoe factory on the one hand and become familiar with the production process.

Even they will control the proportion between new and old machines, and do not introduce too many equipment in the pre production area.

Like Xinhua shoe materials, they introduced advanced computer systems to manage materials and customers in 05 years. Now they have been updated to tenth editions. Through information flow, tens of thousands of categories of products and classified customer information are managed.

"In view of the characteristics of market demand, we should not only play the role of traders, but also make the material cost effective, and we need to provide solutions based on the actual situation of customers to optimize the processing flow of shoes products."

Wang Wei introduced, for example, deep processing for customers to do material bonding, greatly improving customer dependence.

At the same time, they also set up the Xinhua shoe material flying weaving research and Development Center recently, and raised the reaction speed of shoes enterprises to fabrics from the source.

{page_break}

Build regional brand: to improve the quality of production and explore the sales mode.

Quick response ability and precise control of cost are important abilities of three sports shoes to compete in the market.

For the time being, they are unable to match Jinjiang's major sports brands, and gradually occupy the domestic middle market with products of high quality and low price.

"The three shoes are mainly sold domestically before 2012, and then gradually contact with export, which is a key node to enhance product quality."

Wang Hui said when he visited Mao Da shoes and clothing.

Under the guidance of the mechanization consciousness of local shoe enterprises, at present, three shoe factories with 4 production lines are increasing.

"One line can produce 5000 pairs of products, and there is no off-season all year round", but as local businesses continue to strengthen their awareness and awareness of brands, they gradually begin to increase productivity and quality.

"Building brand takes time and needs to be invested, but this is a step by step!" said Wang Zhiyong, chairman of the shoe industry association of Anxin county.

A few days ago, Lining himself had just visited his shoes firm Jixing Yu.

And its own brand U.SHOE has become a microcosm of local shoe industry's pursuit of brand.

At present, the production line of U.SHOE products is controlled between 2000 and 3000, and the quality is constantly improving.

"We are still doing the retail channel test, and we feel a little bit."

The ten wolf shoe industry contacted the electricity supplier channel 6 years ago.

"Two years ago, the results were quite good, and now they are relatively false.

We are still optimistic about and return to the store. "

Liang Zhenjiang said.

In order to support the development of sales channels, Anxin Economic Development Zone has been planned in recent years, and now has developed three parts: Zhang Cun Industrial Park, shoe material trading center and famous brand enterprise gathering area.

But no matter what kind of exploration, the three stations need more contact with the outside world.

This is the intention of several local leading enterprises to jointly establish the footwear industry association of Anxin county.

"If the three shoe industry wants to revive, it will have to go out more and learn from all the major shoe producing areas in the country."

Secretary Wang Wei mentioned.

At the same time, the association will guide enterprises to implement brand strategy and create "made in Baiyangdian" brand.

Under the efforts of many parties, the three shoemaking industry is developing with boundless vitality.

- Related reading

- Industry perspective | The Brand Of The Great Women'S Fashion Brand Is All Buying.

- Men's district | A New Way Of Building A Brand Community Of Literature And Art?

- Company news | The Amount Of YOUNGOR Involved In Litigation Is As High As 800 Million, Investment Business Is Dragging Down, Net Profit Is Down By 91%.

- Expo News | Tian Guo Guo 2018 "0.5M. New Horizon" Perfect Ending

- Shoe Market | Your Gucci Shoes Are Actually The Beginning Of Automation In Robotics.

- Fashion Library | Milan Men'S Wear Week: Prada Sees Surprises From Commonplace

- Foreign trade information | Huge Business Opportunities! CCTV Financial Secret To The Secret Investment In This Country, The Red Bean Group Has Been Successfully Tested.

- Leisure clothes | Adidas Released The 2018 MLS Professional Football League Jersey.

- Fashion Bulletin | MIZUNO Broken Nail Football Shoes Morelia "Leather Shoes" To Understand

- Shoe Market | Adidas World Cup Soccer Shoes Designed For Women Soccer Players

- The Far East Has Become The Partner Of This Year's Adidas Supply Chain For Marine Waste Recycling Materials.

- Small Drama "White Snake" Small Actor At The Press Conference, Is About To Launch Two New Series Of Drama Series.

- Girls Blush Let The Actress Age Reduction, Tang Yan, Zheng Shuang And Guan Xiaotong Are Using.

- The New Height Of "Rouge" Spy War Shows That Zhao Liying, Tao Xinran And Lu Yi Are Arrogant.

- This Late Autumn Does Not Bring Any Color To Your Life.

- 2016 Golden Eagle Festival Gathered Together, Li Xuejian, Hu Ge, Zhao Liying And William Chan Contribute Half Of The Traffic Volume!

- What Should Be Done In The Registration Stage Of Trademark Registration In Yiwu?

- Handling Of The Settlement Of The Collection Of Foreign Collections

- Reception Etiquette In The Work Of The Secretarial Work

- Conversation Etiquette With Customers