What Value Does WMS Warehouse Management System Have For Enterprises?

In today's uncertain world, digital trend is one of the few things that can be confirmed. utilize logistics It has become a general consensus in the logistics industry to realize the digital transformation and upgrading of logistics and improve the efficiency of logistics operation. Especially in warehousing, more and more enterprises use WMS warehouse management system to help manage warehouse operations.

Efficient digital warehouse operation has many significant values for enterprises

First, for product sales, the responsibility of warehouse delivery is to deliver the sales order goods to customers quickly and smoothly. The warehouse operation efficiency is directly related to whether the closed-loop transaction can be completed smoothly or not, and whether the sales results can be finally obtained smoothly.

Second, for supply chain management, warehouse is the core link of logistics, Warehouse operation Efficiency is related to the overall logistics cost reduction and efficiency improvement; On the other hand, as the control center of supply chain inventory management, inventory data guides the purchasing, production and sales strategies of enterprises.

Thirdly, for enterprise management, the supply chain resources, marketing resources and sales rhythm need to be effectively coordinated to avoid the waste of enterprise resources and costs. Enterprise management needs warehouse managers to provide complete and detailed order data, inventory data and other key logistics data as support to help clarify the market situation and enterprise internal situation, so as to make reasonable business decisions.

In a word, more and more enterprises use WMS warehouse management system, which is to help improve warehouse operation efficiency by digital means. On the one hand, it helps to reduce costs and increase efficiency in warehousing and logistics links, on the other hand, it is used to support logistics supply chain management and business decision-making.

From the reality, the warehouse manager, the first undertaker of warehouse responsibility, is always faced with the contradiction of how to improve the actual capacity of warehouse to the theoretical capacity of warehouse. Specifically, warehouse managers are faced with the following dilemmas:

First, the warehouse manager needs to deal with too much transactional work, and his energy is seriously scattered, so he can't continuously pay attention to the overall capacity improvement of the warehouse;

Second, the whole chain data of warehouse is not fully online, so it is difficult to collect data, and the efficiency of warehouse is improved without complete data support.

According to the market situation of WMS warehouse management system, SaaS type WMS warehouse management system is becoming the first choice in the industry, which can effectively solve the problems of enterprises and warehouse managers. Taking the IOT cloud warehouse 50wms warehouse management system as an example, the IOT cloud warehouse 50wms warehouse management system can provide standardized and intelligent warehouse operation process management for a variety of industry customers in B2B and B2C scenarios, and help enterprises to conduct digital management and control of the whole process of warehousing operation. It has the following three distinct highlights:

First, IOT cloud warehouse gives full play to the characteristics of SaaS WMS warehouse management system, which has the remarkable characteristics of "instant use, remote implementation, online management, convenience and quickness", and can help customers quickly realize the online operation of warehousing system.

Second, relying on the logistics scene system service experience of many industry head customers, the 50wms warehouse management system of IOT cloud warehouse has the advantage of being closer to the logistics business scenario. For example, B2C scenario supports efficient bulk order and batch order operation, supports after-sales collaboration and rapid exception handling, and can stably support the delivery of million orders during peak customer periods; B2B scenario combined with IOT cloud warehouse 50tms transportation management system can achieve efficient collaboration of transportation driven warehousing operations.

Third, through the deep experience of serving many leading customers in the industry, IOT cloud warehouse 50wms warehouse management system has been able to highly adapt to cosmetics and skin care, household appliances, food and beverage, etc Shoes, clothes and hats , Ribai fast food, fresh fruit, engineering building materials, bulk materials and other industries of complex warehouse operation scene.

Specifically, IOT cloud warehouse 50wms warehouse management system supports warehouse level warehousing management, inventory management, outbound management, rule strategy, PDA and RFID, client, basic data and configuration, and supports multi warehouse enterprise level partner management, goods management, enterprise data import and export functions.

In a word, with the 50wms warehouse management system of IOT cloud warehouse, the warehouse management can easily realize the automation, intelligence, datalization and visualization of warehouse operation, and obtain the obvious value brought by the 50wms warehouse management system.

Automation and intellectualization: the system guides the warehouse operation and eliminates the ineffective and inefficient transactional work

On the one hand, the 50wms warehouse management system automatically assigns tasks to people through task instructions, so that the receiving, picking, packaging, rechecking and shipping personnel perform their respective duties and efficiently cooperate, which greatly reduces the redundant and ineffective transactional communication between warehouse managers and operators in the working process. On the other hand, 50wms warehouse management system makes the specific operation process of operators online and standardized, reducing the possibility of improper operation of operators, and supports the function of abnormal tracking, which greatly reduces the field management pressure of warehouse managers.

It is worth mentioning that the 50wms warehouse management system supports PDA intelligent voice operation, which can prompt the operation quantity, SKU and other key information, and prompt abnormal information through voice + vibration. In this way, even in the dark working environment of the warehouse, it can maximize the accuracy of warehouse operation, reduce the occurrence of errors, and reduce the working pressure of warehouse management personnel on-site error correction. In addition, the 50wms warehouse management system guides the operators to move in the warehouse through the optimal path algorithm, and supports the packaging recommendation function, which can effectively reduce the time occupation of operators caused by invalid redundant distance and transactional work.

That is to say, as the "organizer, coordinator and manager" of human, goods, field and other resource elements in the warehouse operation site, 50wms warehouse management system can help warehouse managers and warehouse operators deal with invalid or inefficient transactional work automatically and intelligently, so as to achieve the effect of "system replacement and system strength", so as to improve the operation efficiency of the warehouse.

Data and visualization: information collection in and out of the whole process, multi-dimensional report support optimization decision-making

The automated and intelligent operation management support of IOT cloud warehouse 50wms warehouse management system enables the energy of warehouse management personnel to be separated from the complicated transactional work, and focus on the core work of continuous improvement of warehouse capacity. Generally speaking, the 50wms warehouse management system can make the whole process of warehousing and delivery into data, and present it through multi-level reports and visualization tools, so as to help warehouse management personnel clarify the current situation of warehouse operation, timely discover deficiencies and errors, and summarize high-quality experience, so as to provide strong data support for improving warehouse operation efficiency.

The 50wms warehouse management system records the whole process data of warehousing operations, such as "warehousing reservation, supplier supply, warehouse receiving, goods sampling, shelf warehousing, inventory, outbound order, picking, wave number, replenishment, review, packing and labeling, and delivery handover", including multiple dimensional data of "time, quantity, operator", etc, It can effectively help the warehouse management personnel to analyze the operation status of warehouse, such as human efficiency and plateau efficiency, and provide decision-making reference for continuous cost reduction and efficiency increase of warehouse operation.

In other words, the 50wms warehouse management system is just like the "staff and military division" of warehouse management personnel. It collects and records the operation dynamic of the warehouse all the time, and presents it with intuitive actual data. It provides solid support for warehouse management personnel to improve warehouse capacity, and breaks the dilemma of lack of powerful data in warehouse efficiency improvement.

From the development trend of logistics industry, digital transformation and upgrading has become an irreversible development trend. By using SaaS logistics management system such as IOT cloud warehouse 50wms warehouse management system, the digital upgrading and transformation of warehouse operation and management can be realized more quickly and effectively to meet the needs of the overall development of enterprises. The era of digitalization and digital intellectualization has come. Only by actively integrating into the trend of digital logistics can we seize the market opportunity in the industry reform and win the future.

- Related reading

Is Ma Yun Completely Invisible? Ali'S Financial Report In The First Quarter Of Fiscal Year 2022 Transmits Three Signals

|

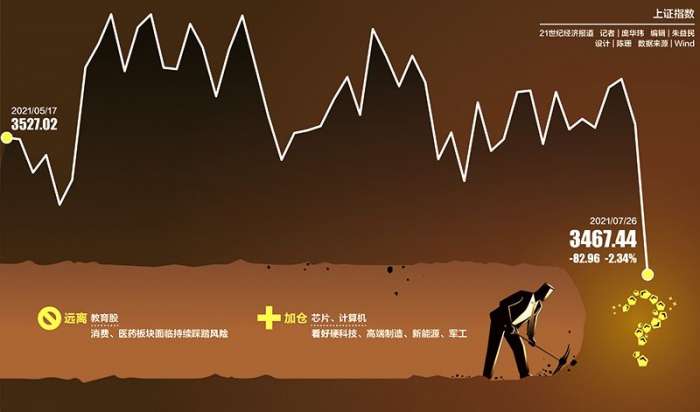

A Shares In Two Days "Evaporation" Of 4 Trillion Market Value Of Foreign Capital Fleeing Private Placement Passive Reduction

|

After A-Share Crash, Institutional Bottom Copy Roadmap Emerges: Away From Education Stocks, Favor "Ning Index"

|- Local hotspot | Xinjiang Textile Strides Forward To "High End + Intelligent + Green"

- Instant news | Sun Ruizhe: Anchoring The New Pattern, Innovating The Future And Opening Up A Bright Road For China'S Garment Industry

- City Express | Shishi Textile And Garment Enterprises Support Xinjiang Cotton

- Local hotspot | 2021 China Textile Cross Border E-Commerce Forum And Resource Docking Meeting Successfully Held

- quotations analysis | Cotton Price In The Current Situation Or Difficult To Get Out Of Trouble

- Market trend | China Textile City: Renmian Creative Color Pattern Fabric Transaction Shock Push Up

- quotations analysis | Market Scale And Development Prospect Forecast Of Home Textile Industry In 2021

- Industrial Cluster | New Cotton Is In Danger Of Disaster Due To Rainstorm In Australia

- Other | Jiangxi Textile Industry High Quality Development Planning Seminar Held In The 14Th Five Year Plan

- Departmental notices | National Bureau Of Statistics Interprets China Purchasing Manager Index In March

- Where Does The Judgment Of Stability And Stability Come From

- Shishi Promotes High Quality Development Of Textile And Garment Industry

- Discussion On Promotion Of National Brand And Promotion Of High Quality Development Of Listed Companies

- Attention: Design Guidance Of 2022 Spring And Summer Women'S Clothing Fabrics

- Tang Chongnian, The Pioneer Of Red Bean'S "Qingbai Annual Report, The Vanguard Of The Party'S Favor Struggle": Pioneer In Business Development, Rooted In The Group Purchase Of Professional Clothes For 20 Years

- Import Cotton Goods To Speed Up, Port Inventory Remains High

- Funeng Shares (600483): No Significant Information Should Be Disclosed Due To Stock Price Changes

- Beiqing Huanneng (000803): 20352554 Restricted Shares Will Be Lifted

- Bank Of China Cashmere Industry ((000982): The Progress Of Equity Transfer Of Participating Companies

- St Gaosheng (000971): Receiving Judgment And Litigation Progress