"Koos" Multi-Functional Shoe Materials: Develop Sustainable Solutions For The Future -

The focus of "Koshi" multi-functional shoe materials is not limited to the trend, but focuses on redefining the shoe industry with breakthrough innovation ability and sustainable development vision. The company is firmly committed to reducing the impact on the environment and is proud to lead this change. With a clear vision and innovative strategy, "Koos" multi-functional shoe materials are focusing on reducing carbon emissions in its entire supply chain, product design and manufacturing process. "Koos" multi-functional shoe materials are striding towards a brighter and greener future, and always adhere to every step. Gunter Scharfenberger, the director of global product innovation and sustainable development of "Coats" multi-functional shoe materials, made a detailed introduction to the company's sustainable development policy, and elaborated on a number of environmental protection and carbon reduction initiatives currently being implemented by the company. ?

"Consumers are paying more and more attention to comfort, performance and sustainability, and the development of shoe material structure components is also driven by these mainstream trends. In terms of comfort, shoe manufacturers are gradually increasing the application of advanced materials in shoe design, and strive to achieve an ideal balance between comfort, flexibility and durability."

"The innovation of footwear design responds to the growing demand of consumers for ergonomics and high-performance footwear, especially in the field of sports. In addition, the concept of sustainable design and production has also become the focus of the brand. The brand hopes to introduce innovative biodegradable materials, recycled plastics and plant based environmental protection alternatives in footwear products, with the aim of reducing the impact on the environment. "

"Over the years," Koos "multi-functional shoe materials have kept improving in the above fields. Comfort and performance are the core of our shoe material components, and the concept of sustainable development is also firmly rooted in our genes. Today, our priority is to find new solutions to meet customer needs in a sustainable way, and take this as the criterion." -

"Koos" multi-functional shoe materials have adopted a comprehensive sustainable development approach: -

Invest in research and development of new materials to reduce the company's dependence on original resources;

Research and develop shoe material products aimed at avoiding waste and promoting recycling;

Improve manufacturing process with new technology to reduce carbon emissions;

Promote transparent and ethical practices throughout the supply chain;

Participate in projects related to environmental protection and social responsibility.

Actively promote carbon reduction goals

"Carbon reduction is the core of the sustainable development strategy." Gaoshi "multi-functional shoe materials have set carbon emission reduction targets covering different ranges, including range 1 (direct greenhouse gas emissions), range 2 (indirect emissions from external input energy) and range 3 (emissions from raw material procurement). These goals are consistent with the company's overall commitment to achieve zero net emissions by 2050. "

Gunter continued: "We have developed a phased implementation path for the short term (to 2026), medium term (to 2030) and long term (to 2050). This phased approach enables us to steadily move towards the goal of net zero emissions while improving operational efficiency year by year."

Principles and policies leading to change ?

In order to achieve the established grand goal, "Koos" multi-functional shoe materials have implemented a number of key policies, including preferential purchase of renewable energy through signing power purchase agreements (PPAs) in feasible areas - this initiative directly addresses the emissions of Scope 1 and Scope 2. If it is not possible in some areas, the company will consider installing renewable energy power generation devices on the site - usually solar power, but still need grid power during the night shift. ?

Carbon emission reduction in production

The company also sets internal energy intensity reduction targets to improve production energy efficiency. The team has taken a number of measures to reduce carbon emissions in product manufacturing. Specific actions include upgrading inefficient equipment, streamlining production processes through process optimization, and deploying real-time energy monitoring systems in the factory.

In addition, the company has adopted a strong material transformation policy, giving priority to low-carbon alternatives such as recycled materials, renewable materials and bio based materials, and gradually replacing high carbon emission raw materials. ?

Gunter said, "There are a lot of renewable materials (such as wood fiber, rice, rice husk and straw) or bio based materials (such as cellulose, sugarcane based EVA and rosin) in the product series of" Coats "multi-functional shoe materials. These materials have the characteristics of carbon neutral or even negative emissions, helping to reduce our own and customers' emissions in the range of 3."

In terms of material procurement, "Koshi" multi-functional shoe materials give priority to materials with low environmental impact, and carefully evaluate them according to product carbon footprint (PCF) data and third-party certification (such as GRS (Global Recycling Standard) and FSC (Forest Management Committee)). ?

At the same time, the company is committed to localization of the supply chain to reduce the transport carbon footprint and incorporate the life-cycle emissions into the consideration of the product design process. ?

Gunter explained: "At the front end of the design, we use digital platforms such as Ecochain and Sphera to assess the carbon footprint of new materials to ensure that the concept of sustainability is embedded in the source of product design. At present, we are systematically promoting the data collection of life cycle assessment (LCA) of all products. "Coats" has three production bases connected to the Ecochain platform, and the 12 month data collection of other production bases and products is in progress. Our ultimate goal is to establish a reliable life cycle assessment report for all products, because carbon dioxide impact is an important measure for discussing sustainable development benefits at the product level.

Close collaboration with customers through innovative closed-loop processes

One of the milestone achievements of "Gaoshi" is the transformation to zero landfill of waste. "Koos" multi-functional shoe materials are committed to ensuring that the waste generated by each production base can be recycled or treated in a responsible manner. "Kaoshi" multi-functional shoe materials know that the path of sustainable development is not limited to their own operations, so they actively encourage customers to reduce waste generation. The company has teamed up with key customers to create a closed-loop plan to enable them to send back production waste, which will then be reprocessed into new products. For example, the recycling of the rear lining - transforming it into a new generation of shoe material components, thereby significantly reducing waste and emissions.

Gunter explained: "Reform 2.0 is our first product developed in this mode: recycling cutting waste from the brand factory, and then processing it into the next generation of sustainable backing."

In 2020, we deepened this technical route - in view of the sharp increase in market demand for finished one-piece shoe materials, the traditional large sheet materials that need to be cut manually still have a large number of applications. We invested in cutting and chipping equipment to transform traditional sheet materials into finished one-piece materials. This not only reduces the pressure on customers to deal with solid waste, allows "Gaoshi" to control the flow of waste, but also avoids unnecessary transportation links. ?

For materials that cannot be recycled within the company, the "Koos" multi-functional shoe materials team will actively seek external suppliers who can use these materials to create value. ?

Gunter added: "We always insist on the priority of material recycling. Even if the pollution level of unrecyclable materials is too high or the composition is too complex, energy recovery is still an effective way of disposal. In accordance with the goal of zero landfill (ZWTLF), we are fully implementing the zero landfill plan for waste in our global production bases."

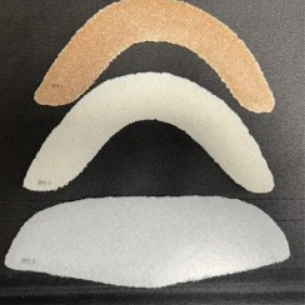

Another commendable technological and product innovation is the company's one-piece shoe materials. Compared with traditional sheets, it can reduce carbon dioxide emissions by up to 50%. Rhenoprint ? The production process is a typical example, which can produce customized shoe material structural parts, such as front lining and rear lining, in a 100% waste free manner. Since no cutting or chipping is required, Rhenoprint ? The process not only realizes zero waste generation, but also saves about 30% of the materials compared with the production scheme using traditional sheet materials.

Facing the Challenge of Decarbonization ?

Although "Koshi" multi-functional shoe materials have made significant progress in the journey of sustainable development, it is not easy to decarbonize the shoe industry. One of the main obstacles is how to balance cost and performance. Gunter said: "The development of cost-effective alternative solutions to replace some complex raw materials, especially the application of new technology materials such as bio based polymers, may be accompanied by high costs." Another obstacle is material supply and scale. The choice of sustainable alternatives to some synthetic materials (such as synthetic latex) is limited, and the supply chain needs to cooperate to develop new environment-friendly materials.

"Koos" multi-functional shoe materials are actively committed to introducing net zero emission products, focusing on gradually improving the sustainability of all products, so as to achieve 100% use of sustainable materials, and finally achieve the goal of net zero emission by 2050. Gunter continued: "Our goal is to gradually improve every product. We do not expect overnight changes, but will continue to optimize products to achieve the ultimate goal." -

Measuring progress ?

In the process of continuous innovation, "Koos" multi-functional shoe materials actively monitor and share their progress. "Tracking progress is key to success, and we use the Greenhouse Gas (GHG) reporting framework to measure our carbon footprint in Scope 1, 2 and 3. This process involves comprehensive cross functional data sharing, which will be included in the monthly reporting indicators of energy, water, waste and materials. " ?

In addition, through its legal and compliance team, "Koos" multi-functional shoe materials can keep abreast of industry legislation, so that they can respond to potential changes in regulations and standards in advance. Almost all production bases of "Coats" have obtained GRS certification, and some of them have also obtained ISO 14001 environmental management certification. In addition, "Kaoshi" multi-functional shoe materials actively participate in relevant activities of various industry organizations, with a view to promoting sustainable development, material transformation and recycling. ?

As sustainable development has become the focus of growing concern in all walks of life around the world, "Koshi" multi-functional shoe materials, while continuing to innovate, have always been committed to reducing the carbon footprint, setting a successful example for the industry.

From the ambitious carbon emission reduction target to innovative product design and responsible manufacturing process, the company is moving towards the goal of achieving net zero emissions by 2050. ?

Finally, Gunter said, "Koos" multi-functional shoe materials are well aware that sustainable development is not achieved by individuals or a company alone, but the responsibility of all mankind. This process involves many aspects, and requires cross industry and cross community cooperation to create lasting and meaningful change. As an enterprise, we are committed to working with customers, partners, suppliers and trade parties to create a more sustainable future for the shoe industry. " ?

- Related reading

"Koos" Multi-Functional Shoe Material Rhenoprinttm Process Innovation: Three RP Series Environmental Protection Gangbao Shoes Help Green Upgrade

|- Industry leader | I Am A Weaver, Featuring In Science And Technology Zhang Guoliang: A Scientist Coming Out Of The Workshop

- Successful case | Use New "Weaving" For The Future! Xia Jin Promotes The Deep Integration Of International "Government, Industry, University, Research And Application"

- Commercial treasure | Product Carbon Footprint Released In The New Spring Of 2025 - Low Carbon Denim Innovation Landscape

- Frontier invention | 戶外功能面料專營區開業,引領輕紡產業新航向

- Business management | 中產協調研山東土工建筑材料行業

- Instant news | What Is Most Relevant To The Textile Industry Is The Introduction Of The Action Plan For Improving Consumption Quality

- City Express | Industrial Cluster: Shaanxi Has Cultivated 17 Textile And Garment Industrial Parks

- Wealth story | China Knitting Industry Association Held A Seminar On The "15Th Five Year Plan" Of Knitting Industry In Shanghai

- Industry leader | The Sixth Batch Of National Level Representative Inheritors Of Intangible Cultural Heritage Was Announced, With 79 Textile Inheritors

- Shoe material | "Koos" Multi-Functional Shoe Materials: Develop Sustainable Solutions For The Future -

- The 4Th Chaoshan International Textile And Garment Expo Was Grandly Opened

- Market Observation: ICE American Cotton Trend Forecast In The Recent Week

- Daikin UNIDYNE Innovation Open Day: Integration And Co Creation To Promote The New Trend Of Green Waterproof

- Innovating And Energizing Fiber Shengze Activating New Quality Productivity Of Traditional Textile Industry

- 山東省濟寧市汶上縣:黨建助力紡織服裝產業向新提質

- Industrial Cluster: Analysis Of Economic Operation Data Of China'S Linen Textile Industry

- Popular Colors: 216 Oriental National Colors Are Revitalized By Applying Traditional Chinese Colors To The Intangible Cultural Heritage Of Color Cards

- Xinjiang Scientific Research Team Solved The Technical Bottleneck In The Production And Processing Of Machine Picked Long Staple Cotton

- Industrial Cluster: Tacheng Region In Xinjiang Accelerates The Transformation And Upgrading Of Textile Industry

- SIUF深圳內衣聯動抖音,攜手行業超頭部品牌,引領消費新潮流